Trenching and Ditching

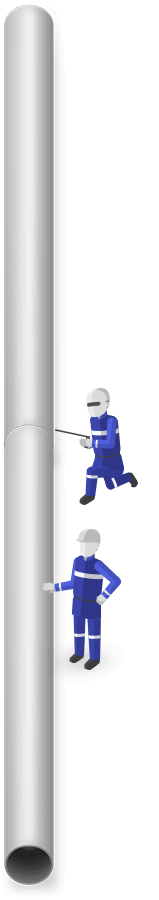

Crews dig a trench along the right-of-way using backhoes and other specialized machinery. Pipelines are buried underground at a safe depth, adhering to regulatory requirements.

TransCanada has an over 65-year track record of safe energy transportation. We operate more than 95,000 km (59,000 miles) of natural gas and liquids pipelines, and move more than 25 per cent of the natural gas used every day across North America.

All aspects of the life cycle of a pipeline – from design and construction to operation and retirement – are guided by our comprehensive Operational Management System and strictly overseen by regulatory agencies and government departments. That's why every TransCanada pipeline is rigorously and precisely built with high-quality materials and the latest proven technology, and monitored by expert staff, every step of the way.

Take the interactive journey with us, and learn about the life cycle of a pipeline from planning to monitoring and beyond.

Long before a single shovel of dirt is lifted, a need for energy comes first. Once that's established, a detailed plan is developed that goes through a series of applications and approvals. Here's an overview.

One of the most important elements of designing a new pipeline is determining its route. Where possible, TransCanada tries to minimize the route length and use existing pipeline right-of-ways or other previously established corridors, to reduce social and environmental impacts.

Where a new right-of-way must be established, TransCanada works with landowners, stakeholders and Indigenous communities to ensure that valuable information is gathered and incorporated into the final route.

First things first: we respect the land and the environment. That's why we always:

Caring for the environment – stewardship, protection and performance

926 kb View NowWe care about climate change

700 kb View Now

Next, our team goes on site along the route to perform detailed studies, conduct surveys and to engineer the overall design.

We meet with local communities early and often to have conversations, gather input and share our plans. We're both proud and committed to the relationships we have with landowners, municipalities and Indigenous groups across North America.

Once we've consolidated feedback and prepared our application, we submit it for regulatory review.

Our regulatory applications contain all the necessary information about a pipeline project – including everything from the proposed route, to the number of municipalities, to the locations of migratory birds. It's not unusual for regulators to have specific questions about a project application. When they do, we submit responses and ensure their questions are answered comprehensively.

We only use high-quality materials and the latest proven technology. All stages of our pipeline construction are completed by TransCanada contractors that must meet our strict qualifications and standards.

On some projects, a temporary workspace is created, with access roads, contractor yards and camps, allowing us to further prepare for the work to come.

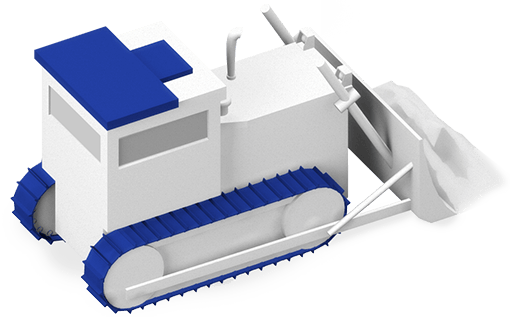

Once surveying is complete, various types of equipment are used to clear the right-of-way. All trees and brush will be removed.

A safe working surface is then prepared by stripping and storing the topsoil layer and grading the subsoil.

Our contractors separate and conserve the topsoil removed from the right-of-way, so it can be replaced once construction is complete. Topsoil conservation ensures the land is returned to an equivalent environmental capability and productive capacity upon completion of the project.

Protecting biodiversity

2.6 MB View NowProtecting the land

2.5 MB View Now

Crews dig a trench along the right-of-way using backhoes and other specialized machinery. Pipelines are buried underground at a safe depth, adhering to regulatory requirements.

Safeguarding water is a top priority. Information is gathered about water bodies along the proposed pipeline right-of-way, including studies of the aquatic environment – such as water flow, bank stability, the quantity and quality of fish habitat, wildlife and vegetation. For all water crossings, the ability of ecosystems to recover after construction is carefully considered.

How we protect water

1 MB View NowStringing is the process of placing pre-coated pipe next to the trench.

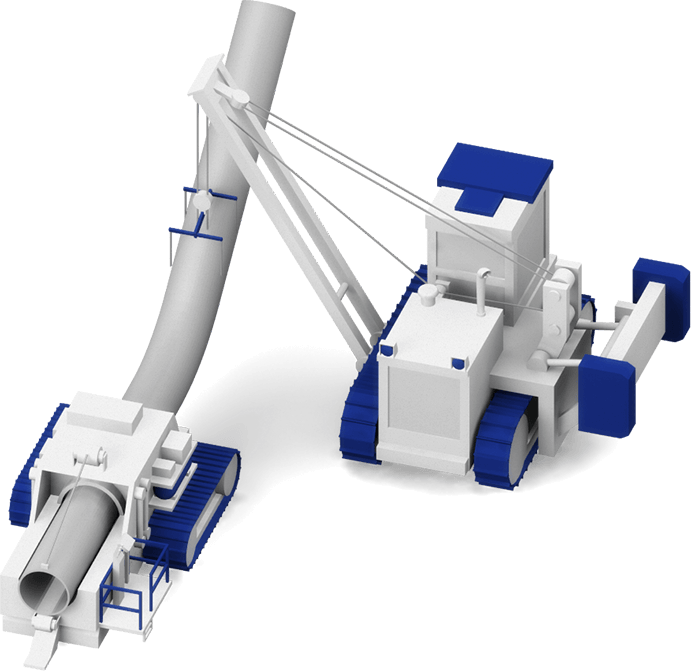

Depending on the terrain and route of the trench, we may need to bend the pipe with special machines to ensure a precise fit.

Once the segments of pipe are lined up, welding can begin. Various techniques and technologies ensure our high-quality steel pipe is welded together in one string. Each connection is inspected and must meet strict safety and quality assurance requirements.

Throughout construction, all welds are checked by an X-ray or ultrasonic process to verify each weld is sound and the pipeline is safe.

The surface of the pipeline is coated for protection. Where the pipeline has been welded, a liquid bond epoxy is applied to help protect the weld. After coating, a technique called “jeeping” detects chips or flaws in the coating and, if required, a new coat is applied to the affected area.

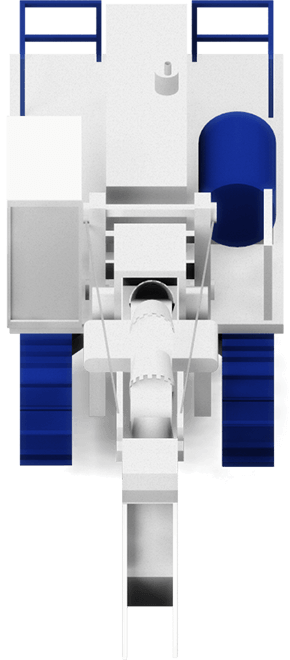

The welded pipeline is lowered into the trench with side booms. A separate crew completes the final welds (tie-ins), connecting continuous lengths of pipeline to the existing system.

Crews dig a trench along the right-of-way using backhoes and other specialized machinery. Pipelines are buried underground at a safe depth, adhering to regulatory requirements.

Protecting the land

2.5 MB View Now

Safeguarding water is a top priority. Information is gathered about water bodies along the proposed pipeline right-of-way, including studies of the aquatic environment – such as water flow, bank stability, the quantity and quality of fish habitat, wildlife and vegetation. For all water crossings, the ability of ecosystems to recover after construction is carefully considered.

How we protect water

1 MB View Now

Stringing is the process of placing pre-coated pipe next to the trench.

Depending on the terrain and route of the trench, we may need to bend the pipe with special machines to ensure a precise fit.

Once the segments of pipe are lined up, welding can begin. Various techniques and technologies ensure our high-quality steel pipe is welded together in one string. Each connection is inspected and must meet strict safety and quality assurance requirements.

Throughout construction, all welds are checked by an X-ray or ultrasonic process to verify each weld is sound and the pipeline is safe.

The surface of the pipeline is coated for protection. Where the pipeline has been welded, a liquid bond epoxy is applied to help protect the weld. After coating, a technique called “jeeping” detects chips or flaws in the coating and, if required, a new coat is applied to the affected area.

The welded pipeline is lowered into the trench with side booms. A separate crew completes the final welds (tie-ins), connecting continuous lengths of pipeline to the existing system.

In the final step of construction, the trench is backfilled with the original subsoil and topsoil to cover the pipeline. In some cases, where the terrain is rocky, padding may be needed to protect the pipeline coating.

Once the trench is backfilled, a series of tests are completed. One key test is called hydrostatic testing, which verifies the pipeline's integrity. Water is placed into the pipeline and pressurized to a level higher than the level the pipe will experience during regular operation. If a leak occurs during testing, we repair or replace the affected section and don't put it into service until it has been tested and deemed safe.

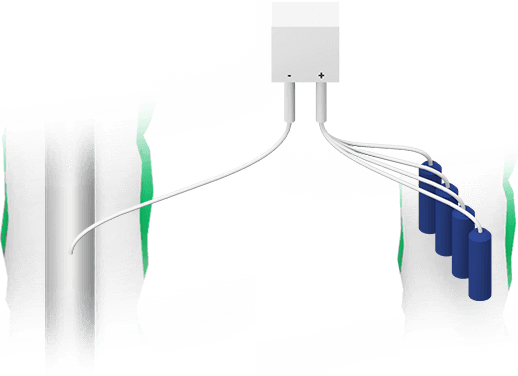

A very low voltage electrical current called cathodic protection is applied to the pipe. The applied current protects the pipe from corrosion as well. The cathodic protection system is monitored on a regular basis to ensure proper operation.

The final step of construction is to reclaim the right-of-way. Great care is taken to return the land along the pipeline right-of-way to the original condition, use and biological diversity that existed prior to construction.

Reducing our environmental footprint

1.7 MB View NowOur number one priority is your safety. Our goal is to ensure that our pipelines operate safely every day and that the public, our employees and the environment are never negatively affected by an incident involving our assets. Here's how we do it.

Our entire pipeline transmission system is monitored 24 hours a day by highly trained TransCanada employees from computerized operation control centres. Satellite technology sends messages to the centre every five seconds to ensure continuous measurement and monitoring of pipeline flow, pressure, temperature and equipment status.

This is one of the many ways TransCanada closely monitors conditions along the pipeline to ensure it is operating safely for the public, our employees and the environment.

Our pipelines are also monitored in other ways, including:

In the rare instance of an alert, our system notifies operators so the appropriate response can be taken.

We have a top industry record for safe operations; however, we still believe every incident is preventable and continue toward our goal of realizing zero safety incidents. Being prepared for the rare cases when something does go wrong is part of our commitment to ensuring the safety of the communities where we operate.

In the event of an emergency, our goal is to ensure an effective, coordinated response to contain and control any incident to minimize harm to people, property, the environment and company operations.

Learn more about our emergency preparedness planning.

Our pipeline safety programs are among the most robust in the industry. From pipeline integrity initiatives to investing in leak-detection technology and public awareness programs, safety is the common link behind everything we do.

For over half a century, we’ve been instrumental in testing new technology to maximize pipeline efficiency – from safety improvements to minimizing emissions and more. All to ensure our pipelines – and the communities they serve – are safe.

Learn more about technology and innovation.

While we have strong maintenance and pipeline integrity programs, some of our energy infrastructure is aging and we are planning for the safe retirement of our pipelines when they are no longer needed.

Caring for pipelines throughout their life cycle includes removing aging pipelines from service. While properly monitored, inspected and maintained pipelines are built to last for decades, eventually shippers no longer need to transport their product on our pipeline systems.

If you've had pipeline on your property for many years, nothing will change. TransCanada will pay for all costs associated with the retirement including clean-up of the surrounding area and reclamation to current environmental standards. We will ensure that the pipeline is retired safely and with minimal impacts to landowners or the environment.

Learn more about Canadian National Energy Board (NEB) regulatory applications.